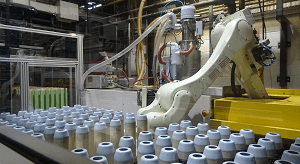

Benefits of automated production lines

Industrial robots provide numerous benefits to the production floor. Because accuracy and repeatability are the two key features of a robot, consistent quality can be achieved. It also contributes to the reduction of labor costs and workforce shortages.

The basics of industrial robots

Industrial robots have been chosen as the ticket for automation solutions. Learn about the history of industrial robots and their categories.

Important steps of the robot deployment

“What tasks can we leave to the robot?” “What steps do we need to take?” “Who can we talk to and get some advice?” When it comes to actually deploying a robot, many companies are unable to go forward from square one. Here are some of the basic steps you’ll need to take to successfully deploy a robot and maximize its capabilities to achieve desired outcomes.

Why choose Kawasaki Robotics

Kawasaki Heavy Industries was one of the first companies to manufacture and sell industrial robots in Japan, the world’s predominant robot manufacturing country. As an all-around engineering company with technologies that serve areas covering land, sea, and air, we have always developed the most advanced robots. We also provide comprehensive customer support to cover the entire life-cycle of a robot, from installation to operation.

Learn more about Kawasaki’s industrial robots

Product Information

Case Studies

Contact Us

Kawasaki Robotics (UK) Ltd

Tel: +44(0)1925 5713000

Email: info@kawasakirobotuk.com

News & Updates

News

Kawasaki Robotics Presents ‘Ask the Experts’ Facility at Mach 2020

Blog